| Payment Type: | L/C,T/T,D/P |

|---|---|

| Incoterm: | FOB,CFR,EXW |

| Min. Order: | 1 Set/Sets |

| Delivery Time: | 30 Days |

Basic Info

Model No.: TDTG14 TDTG20 TDTG30 TDTG40 TDTG50 TDTG60 TDTG80

Type: Flour Mill

Application: Flour, Wheat, Starch

Voltage: 380V

Condition: New

Customized: Customized

Additional Info

Packaging: Marine Fumigation Packaging

Productivity: 1-200t/h

Brand: PINGLE

Transportation: Ocean,Land,Air

Place of Origin: CHINA

Supply Ability: 5 Set Per Month

Certificate: ISO9001:2015

HS Code: 84378010

Port: Tianjin Port,Qingdao Port,Shanghai Port

Product Description

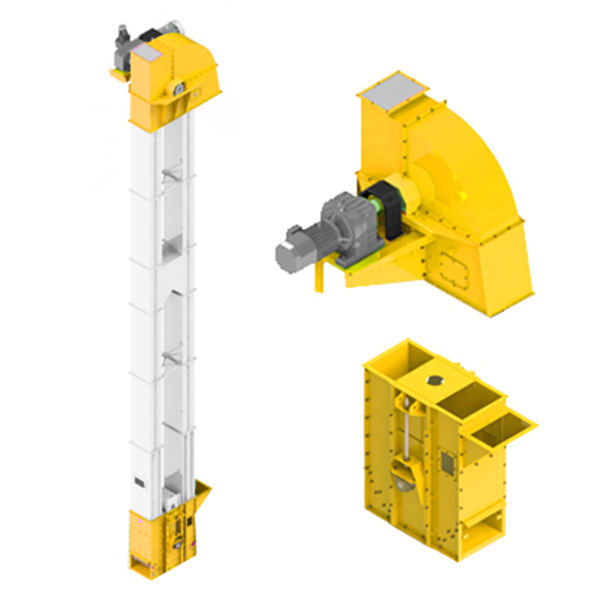

Part 1: Product Technical characteristics

The assembled structure reduces welding distortion and provides good sanitary.

2. Split-type head section makes maintenance simple and convenient.

3. Speed switch and backstop ensure safe and reliable operation.

4. Wearable parts use special wear-resistant materials to achieve longer service life and higher operational reliability.

5. It can be equipped with deviation detector according to the user's requirements to realize the monitoring of equipment and ensure that the equipment runs without fault.

6. The high handling capacity elevator adopts gravity tension and screw tension to make the bucket belt tension easier

Bucket Elevator Main Use:

TDTGE bucket elevator is suitable for vertical material transportation of bulk storage and conveying facilities (warehouse elevator, silo) with high production capacity. Material suitable for transportation includes cereals, animal feed, granules, oils, derivatives, meals and flour. TDTGE bucket elevator has a very high production capacity and is mainly used in port terminals and processing plants. Widely used in grain depots, flour mills, grain and oil processing plants

Technical parameter table

|

Model |

Conveying Capacity(t/h) |

Power(kw) |

Max. Lifting Height |

|

|

Granular material(r=0.75) |

Powder material(r=0.43) |

|||

|

TDTGE14/10 |

1-3 |

0.5-1.5 |

0.55-0.75 |

12 |

|

TDTGE20/13 |

3-7 |

1-2.5 |

1.1-1.5 |

16 |

|

TDTGE30/13 |

6-10 |

3-5 |

1.5-3 |

25 |

|

TDTGE30/18 |

15-30 |

5-10 |

2.2-4 |

25 |

|

TDTGE40/18 |

15-35 |

6-12 |

3-7.5 |

32 |

|

TDTGE40/23 |

20-40 |

8-12 |

3-7.5 |

32 |

|

TDTGE50/28 |

50-60 |

15-20 |

4-15 |

40 |

|

TDTGE60/33 |

70-100 |

20-30 |

7.5-22 |

45 |

|

TDTGE80/47 |

160-200 |

|

22-45 |

45 |

Part 2: PINGLE Group Production Workshop and Advanced Productive Equipment

Milling Machinery Productive Workshop

Milling Machinery Productive Workshop

Productive Equipment: Laser Cutting Machine, Vertical Machining Center, Numerical Control Bender and Horizontal Machining Center etc.

Part 3: PINGLE Quality Management Certification

PINGLE ISO9001:2015 Management System

PINGLE CE Certification

CONTACT US

HEBEI PINGLE FLOUR MACHINERY GROUP CO., LTD

Contact Person: Zuo Kun

Phone:86-311-88268111

Fax:86-311-88268777

Address: XIPINGLE TOWN,Shijiazhuang,Hebei